The air pressure regulator reduces the pressure of the incoming high and unstable air source and maintains it at a constant, available set value, regardless of how the air source pressure or downstream (outlet) flow changes.

To protect your pneumatic system, you need to know how to choose the appropriate regulator type. In this blog, we will come to understand the air pressure regulator.

Types of Air Pressure Regulators

According to the working principle of classification:

Overflow Regulator

When the outlet pressure exceeds the set value, the internal relief valve (exhaust valve) automatically opens, and the excess gas is discharged to the atmosphere, so that the pressure quickly drops to the set value.

Non-overflow regulator

The non-overflow regulator does not have an automatic exhaust function. When the outlet side pressure is higher than the set value, the pressure can only be slowly reduced through the consumption of downstream equipment or internal leakage.

Pilot regulator

The pilot regulator adopts two-stage control. A small precision pilot valve senses pressure and controls a large flow main valve. It is usually combined with an electrical proportional valve to realize electrical signal control.

| Types | Features |

| Overflow Regulator | The response speed is fast and the pressure control is accurate.Exhaust when decompression, may produce noise, will waste a small amount of air.It is not suitable for situations where exhaust is not allowed or expensive and harmful gases are used. |

| Non-overflow regulator | No exhaust, zero gas consumption, energy saving and environmental protection.The response speed is slow, and the recovery time after pressure overshoot is long.After closing the downstream valve, the pressure may rise due to temperature rise (pressure locking phenomenon) |

| Pilot regulator | The control precision is very high and the stability is good.The flow capacity is very large, which can meet the demand of large gas consumption.The structure is relatively complex and the price is high. |

There are many types of air pressure regulators on the market, which are suitable for different applications and pressure control requirements.

Standard Regulators

The standard regulator is widely used in pneumatic tools and equipment that require stable working pressure, and is most commonly used to regulate the pressure from the main pipe of the air compressor air pressure regulator (air compressor air pressure regulator).

Precise regulators are used in occasions where extremely high precision and sensitivity are required. They usually have a finer adjustment mechanism and higher sensitivity.

For example, measuring equipment, calibration tools or advanced automation processes.

High Flow Regulators

The large flow regulator is used to deal with very large airflow at low pressure drop, which is common in the main gas source line or large mechanical equipment.

Inline Regulators

The inline air pressure regulator is a compact design, usually installed directly near the inlet of the pneumatic tool or in the windpipe, for local or point-to-point pressure fine-tuning to meet the needs of specific tools.

Applications

Industrial automation: used to control the operating pressure of cylinders, pneumatic motors and fixtures.

Pneumatic tools: Ensure that pneumatic tools such as spray guns, sanders, impact wrenches, etc. obtain the correct operating pressure, for example as part of the air pressure regulator for air compressors.

HVAC system: used to control pneumatic actuators and air doors.

Medical equipment: For precise pressure regulation in certain medical or laboratory gas control systems.

Tire inflation: control inflation pressure to prevent overcharge.

Paint spraying: The air pressure regulator valve with gauge is used to precisely control the spraying pressure to obtain a consistent surface treatment effect.

Selection Criteria

The following key factors need to be considered to select the appropriate air pressure regulator :

| Criteria | Description |

| Maximum inlet pressure | The regulator must be able to safely withstand the highest pressure of the gas source. |

| The required outlet pressure range | The regulator must be able to meet the minimum and maximum working pressures required for your application. |

| Traffic demand | The flow coefficient (Cv) of the regulator must be high enough to meet the maximum airflow required by the downstream equipment without causing excessive pressure drop. |

| Accuracy and sensitivity | Determine whether your application requires a standard or a precision regulator. |

| Fittings dimension | Ensure that the regulator ‘s inlet and outlet dimensions are compatible with your pipe or hose. |

| Environmental condition | Consider working temperatures, humidity, and corrosive environments (stainless steel or specific materials may be required). |

Step 1: clarify the core technical parameters

Inlet pressure

What is the maximum pressure that your compressed air system can provide? (e.g., 0.8 MPa, 1.0 MPa).

The maximum inlet pressure of the regulator must be higher than the maximum pressure of the system, leaving a safety margin (usually 1.5 times). This is the safety bottom line.

Export pressure

How much working pressure does your pneumatic equipment need? (e.g. 0.4-0.6 MPa).

Adjustment range: The regulator’s outlet pressure adjustment range must cover the working pressure you need.

Setting accuracy: Do you need precise adjustment ? Ordinary applications can be selected ± 0.05 MPa, precision control (such as instrumentation, spraying) requires ± 0.01 MPa or higher accuracy.

Flow capacity

What is the air consumption of the downstream equipment during normal operation? The total gas consumption of all equipment working at the same time is calculated, and the peak flow is considered.

The flow coefficient or rated flow of the regulator must be greater than your maximum demand flow. Too small selection will lead to:

- Outlet pressure drop ( ‘pressure drop’ )

- Insufficient flow, slow equipment action

- The regulator continues to work at full load and its life is shortened.

Step 2: Determine the function and configuration requirements

Interface dimensions and threads

The size and type of the inlet and outlet threads of the regulator must match your pipeline (such as G thread, NPT thread, Rc thread, etc.). Commonly used sizes are 1/8′, 1/4′, 3/8′, 1/2′ and so on.

Do you need a pressure gauge ?

It is strongly recommended to select a model with outlet pressure gauge for intuitive setting and monitoring of pressure.

High requirements: Some applications need to monitor the inlet pressure at the same time, and dual phenotypes can be selected.

Is filtration and lubrication required?

FRL combination: If your air source is not clean, or downstream equipment needs lubrication, you should choose :

Pressure regulating valve with filter: it can filter water and particles (such as 5μm or 40μm).

Pressure regulating valve with oil injector: it can add oil mist to the air, lubricate the cylinder and other equipment.

If there are independent filters and oil misters, a single adjustment function can be selected.

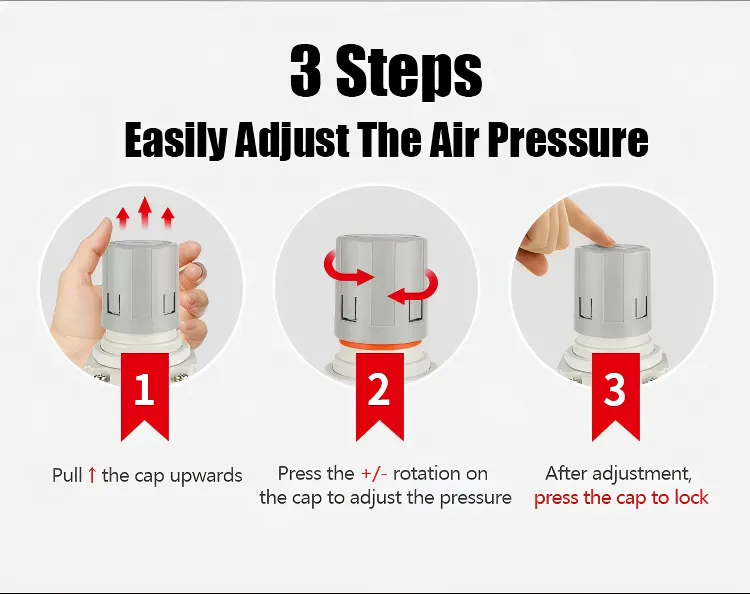

Mode of adjustment

Manual adjustment: the most commonly used, through the knob setting.

Lock function: to prevent the set value from accidentally touching change.

Remote/electrical control: The pressure is remotely adjusted by an external electrical signal (such as a proportional valve) for an automated system.

Exhaust mode

Pressure relief type: when the outlet pressure setting value is lowered, the excess pressure will be automatically discharged to the atmosphere, and the response is faster.

Non-pressure relief type: the excess pressure is slowly balanced through the interior, which is suitable for environments where exhaust is not allowed (such as harmful gases).

Step 3: Assessing the work environment and special requirements

Material

Valve body:

- Brass: universal, good corrosion resistance, suitable for most industrial environments.

- Aluminum alloy: lightweight, low cost.

- Stainless steel: for corrosive environments ( chemical, food, marine ), high cleanliness requirements or external corrosive atmospheres.

Internal seals:

- Nitrile rubber: standard choice, suitable for ordinary air and a small amount of oil.

- Fluorine rubber: high temperature resistance, chemical corrosion resistance.

- Polytetrafluoroethylene: It is suitable for oil-free air or special gas with low friction coefficient.

Environment and medium conditions

Temperature range: Are the ambient temperature and medium temperature within the operating temperature range of the regulator?

Air quality: Is the air oil-free? Is it extremely dry? This will affect the choice of sealing materials.

Hazardous areas: Do you need explosion proof certification? (e.g. ATEX for Europe, IECEx for international, or Chinese explosion protection standards).

Industry Compliance and Certification

Food/pharmaceutical: to meet health standards, such as FDA certified materials, easy to clean design, usually stainless steel.

Medical treatment: high cleanliness and reliability are required.

Installing An Air Pressure Regulato

1. Preparation

Disconnect the gas source: Before installation, be sure to close the gas source and release all residual pressure in the pipeline.

Cleaning: Clean up all dirt and debris on the pipe or connector.

2. Installation location

Upstream filtration: In order to protect the regulator, it is generally recommended to install a filter upstream of the regulator to remove water, oil and particulate matter from the compressed air. This prevents the regulator seat from being worn or clogged.

Direction: The in-line air pressure regulator usually has an arrow mark indicating the direction of the airflow. Ensure that the regulator is installed in the correct direction (the inlet is connected to the air supply and the outlet to the downstream equipment).

3. Connection and sealing

Use appropriate thread sealants (such as Teflon tape or liquid sealant) to connect the pipe to ensure air tightness.

Avoid excessive tightening to prevent damage to the regulator shell or connector.

4. Pressure setting

Slowly open the air supply, allowing the pressure to fill the system.

Using the adjustment knob or handle, the outlet pressure is slowly adjusted to the desired set value according to the reading on the air pressure regulator with the pressure gauge.

Check the pressure reading when there is air flow through to ensure that the pressure remains stable under working conditions.

Q1: How to Tell If An Air Pressure Regulator Is Bad?

By observing whether the outlet pressure cannot be adjusted, seriously fluctuates or continuously leaks, and whether the downstream equipment is abnormal or weak, it can quickly determine whether the pressure regulator is damaged.

Q2: What Is the Life Expectancy of An Air Pressure Regulator?

The life expectancy of the air pressure regulator is not fixed, usually in the millions of cycles or years of stable operation, but its actual life is highly dependent on air quality, workload, maintenance and use of the environment, in harsh conditions may be seriously shortened.

Q3: What Happens If An Air Pressure Regulator Fails?

If the pressure regulator fails, the most dangerous consequence is the output pressure out of control soared, leading to downstream equipment, pipeline overpressure burst, causing serious safety accidents and equipment damage.

Q4: Can l Use An Air Compressor without A Regulator?

Usually, it is strongly not recommended to directly use an air compressor without a regulator. Doing so is very dangerous, can damage equipment, and may lead to serious safety accidents.

Q5: Is the Air Pressure Regulator and the Pressure Reducing Valve the Same Thing?

In the field of pneumatics, Air Pressure Regulator is a pressure reducing valve dedicated to compressed air. Both of them have the same function : reducing the high pressure to a controllable low pressure.

However, in some industries, pressure reducing valves may be a more general term for liquids or steam. The air pressure regulating valve is a specific device for this purpose.