Stainless steel mini cylinder are essential actuators in automation equipment, widely used in industries such as food processing, medical devices, precision instruments, and electronics manufacturing-especially where corrosion resistance and compact size are required. As automation continues to advance, customers increasingly demand standardized and modular cylinder products during selection, design, and procurement.

Cylinder Symbol, which condense cylinder parameters and functions into concise codes, not only facilitate technical communication but also greatly improve selection efficiency and accuracy. This article systematically explains the product symbol system for stainless steel mini cylinders, helping users quickly understand and correctly use various symbols for efficient selection and procurement.

Basic Structure and Common Models of Stainless Steel Mini Cylinders

Main Structural Components

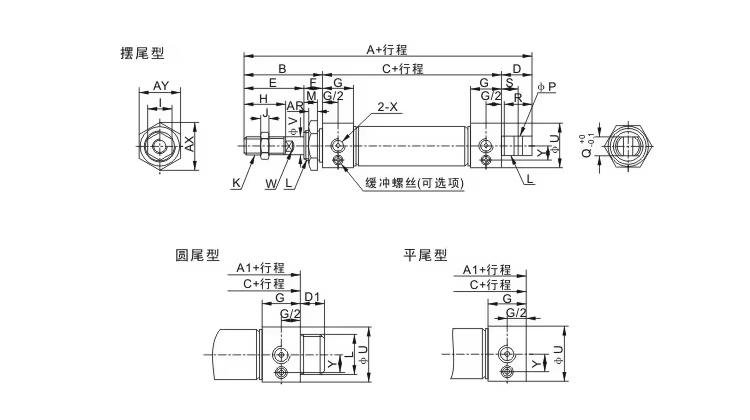

Stainless steel mini cylinders typically consist of a cylinder body, piston, piston rod, seal, end caps, and cushioning devices. The cylinder body is made from high-quality stainless steel, providing excellent corrosion resistance and strength-ideal for long-term operation in harsh environments.

Common Models and Naming Rules

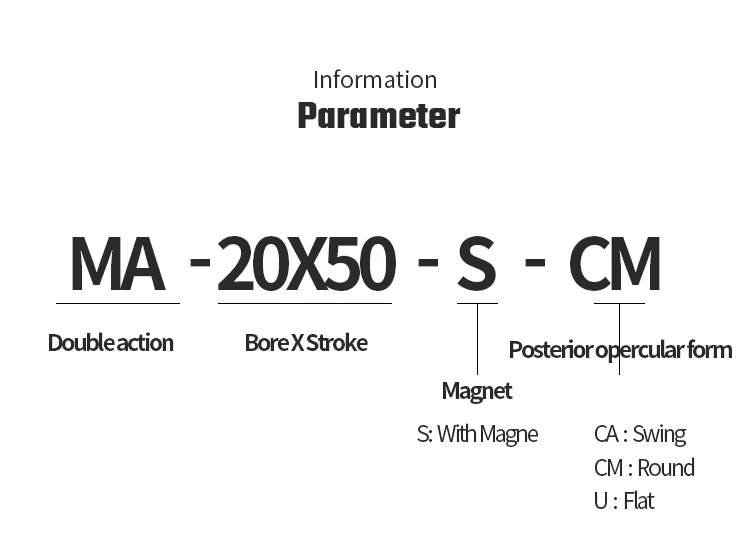

Popular stainless steel mini cylinder models on the market include the MA series, SM series, and AVENTICS S series. Different manufacturers may have their own naming conventions, but model codes generally include key information such as bore size, stroke, and mounting style. For example:

- MA25x100-S-CA (MA series, 25mm bore, 100mm stroke, magnetic type, single clevis mounting)

- SMCJ32x25-20-S-CM-P (SM series, 32mm bore, 25mm stroke, magnetic type, round tail)

Role of Cylinder Symbol

Product symbols are concise codes representing the main parameters and functions of cylinders. They are widely used in technical documentation, selection manuals, product labels, and procurement contracts. A standardized symbol system enables users to quickly identify cylinder specifications, facilitating efficient communication with manufacturers and suppliers.

Correspondence Between Symbols and Parameters

Each symbol corresponds to a specific parameter, such as bore size, stroke, mounting style, or additional features. A standardized symbol system reduces selection errors and improves procurement efficiency.

Detailed Explanation of Common Stainless Steel Mini Cylinder Symbol

Bore Size Symbols

Usually represented by numbers such as 6, 10, 12, 16, 20, 25, 32, 40mm, directly indicating the cylinder’s inner diameter.

Stroke Symbols

Numbers indicating the maximum piston travel, such as 10, 25, 50, or 100mm.

Mounting Style Symbols

Common codes include CA (single clevis), CB (double clevis), FA (front flange), FB (rear flange), and LB (foot mounting), identifying the cylinder’s mounting configuration.

End Cap and Port Symbols

Examples include S (standard), N (non-standard), M (magnetic), and P (cushioning), indicating end cap structure or special ports.

Special Features and Additional Options Symbols

Examples: M (magnetic), C (cushioning), S (non-magnetic), T (high temperature), F (corrosion-resistant), etc., to meet various application requirements.

Symbol Combinations and Selection Examples

Typical Model Cylinder Symbol Combination

For the MA series: MA-20×50-S-CM

Selection Process Example

Suppose a customer needs a stainless steel mini cylinder with a 32mm bore, 25mm stroke, magnetic type, no bracket, and round tail. The model code would be: SMCJ32x25-20-S-CM-P. By combining symbols, users can quickly identify the required product.

Common Symbol Misunderstandings and Precautions

Common Symbol Confusions

For example, “M” may represent “magnetic” or sometimes “cushioning,” so always check the context or product manual for confirmation. Mounting style symbols like CA, CB, FA, etc., may vary slightly between manufacturers, so refer to the manufacturer’s documentation.

Precautions During Selection and Ordering

Always confirm the meaning of each parameter symbol to avoid mismatched products due to symbol misunderstandings. It is recommended to communicate with the manufacturer’s technical staff to confirm the symbol system and any custom requirements.

The system for stainless steel mini cylinder symbol is a crucial tool for efficient selection and technical communication. Clear, standardized symbols help customers accurately express their needs and enable manufacturers to standardize production and service.

We hope this guide helps users understand the meanings and usage of various symbols, improving selection efficiency and reducing communication costs. If you have special requirements or questions, please feel free to contact us. We are ready to provide you with professional technical support and customized services.