What are Stainless Steel Mini Cylinder?

Stainless steel mini cylinder are compact, lightweight pneumatic cylinders made from stainless steel, widely used in industries requiring corrosion resistance and high-temperature stability. As automation and precision manufacturing evolve, the demand for these cylinders continues to grow due to their ability to operate effectively in tight spaces.

Stainless steel mini cylinder are devices that utilize compressed air or gas to drive a piston for linear motion. They are characterized by their small size, light weight, corrosion resistance, and high-temperature stability. These features make them suitable for environments where other materials might fail, such as chemical plants and food processing facilities.

Function and Operation

Stainless steel mini cylinders operate by using compressed air to drive a piston, enabling push, pull, open, and close actions. Their small size and light weight make them ideal for applications where space is limited, such as in precision machinery and robotics.

Advantages and Disadvantages

Stainless steel mini cylinder offer several key advantages and disadvantages:

Advantages:

- Corrosion Resistance: These cylinders provide excellent resistance to corrosion, making them ideal for use in chemical environments where exposure to corrosive substances is common. For example, in chemical processing plants, they can withstand the harsh conditions without degrading over time.

- High-Temperature Resistance: Their ability to maintain performance in extreme temperatures ensures reliability in applications like furnace control systems. This feature is particularly valuable in industries where equipment must operate consistently across a wide range of temperatures.

- Durability and Reliability: Stainless steel mini cylinders are durable and reliable, offering a long lifespan with low maintenance costs. This makes them particularly suitable for industries where downtime can be costly, such as food processing and medical equipment manufacturing.

- Hygiene: They are easy to clean and resistant to corrosion from cleaning agents, making them suitable for use in food and medical industries where hygiene is paramount.

Disadvantages:

- Higher Cost: Compared to cylinders made from other materials, stainless steel mini cylinders are more expensive. However, their long-term benefits often outweigh the initial investment due to their durability and reliability.

- Complexity in Manufacturing: The manufacturing process for these cylinders is complex and requires specialized equipment and expertise. This complexity can lead to higher production costs and longer lead times.

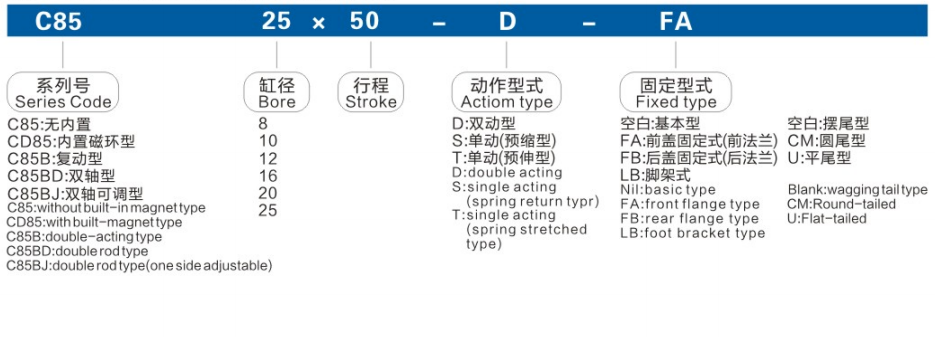

Common Types

Single-Acting Cylinders: These cylinders are designed for applications requiring only one-way motion. They are often used in simple mechanisms where the return stroke is achieved by an external force, such as gravity or a spring.

Double-Acting Cylinders: Providing two-way motion, these cylinders are used in applications requiring both push and pull actions, such as in robotic arms.

Cushion Cylinders: Equipped with cushioning devices, these cylinders reduce the impact at the end of the stroke, making them ideal for applications where smooth motion is crucial, such as in precision assembly lines.

Applications

Automation and Robotics: Stainless steel mini cylinders are widely used in automation and robotics systems to actuate small parts or components. Their compact size and corrosion resistance make them ideal for precision machinery, where reliability and accuracy are critical. For instance, they can be used in robotic arms to handle delicate tasks with precision.

Food Processing: In food processing, these cylinders are essential for moving or positioning food products or packaging. Their hygienic design and corrosion resistance ensure compliance with strict sanitation standards, making them suitable for applications like filling, packaging, and food handling. The ability to withstand harsh washdown protocols, which often include caustic chemicals and high-pressure water jets, further enhances their utility in this sector.

Medical Equipment: Stainless steel mini cylinders are used in various medical devices and equipment, such as pumps, ventilators, and diagnostic equipment. Their reliability and cleanliness are crucial in medical settings, where precision and hygiene are paramount. They can withstand regular cleaning and sanitization, ensuring that medical equipment remains free from contamination.

Industrial Machinery: These cylinders are widely applied in machine tools and packaging machinery, where durability and low maintenance are essential. Their ability to operate in harsh environments, such as those involving exposure to chemicals or extreme temperatures, makes them ideal for demanding industrial applications.

Stainless steel mini cylinder, with their excellent performance and wide range of applications, are essential components in modern industries. As technology advances and market demand grows, they will continue to play a significant role in the future, particularly in industries requiring precision, reliability, and hygiene.