Pneumatic air cylinder are essential actuators in industrial automation and mechanical manufacturing. Thanks to their simple structure, quick response, and easy maintenance, they have become the preferred equipment for many companies looking to improve production efficiency. If you’re wondering how to select the right pneumatic air cylinder or facing issues during use, this article is for you. We’ll dive into selection tips and answer common questions, helping you make smart purchasing decisions and ensure stable, efficient equipment operation.

Basic Types of Pneumatic Air Cylinder and Application Scenarios

First, understanding the types of pneumatic air cylinders is the foundation of proper selection. Different types are suitable for different applications. Common types include:

- Standard Cylinders

The most common type, suitable for general linear motion needs. Simple structure and affordable, ideal for automated assembly lines and packaging machinery. - Compact Cylinders

Designed for limited spaces, such as electronics manufacturing equipment and precision instruments. - Guided Cylinders

Offer strong lateral load capacity, perfect for applications requiring anti-rotation or with significant side forces, such as stamping machines. - Rodless Cylinders

Transmit force via magnetic coupling, with no piston rod. Suitable for long strokes in space-constrained environments. - Locking Cylinders

Equipped with a braking device, ideal for holding positions or preventing load slippage.

Each cylinder is designed for specific industrial needs. Choose according to your actual working environment and functional requirements.

Selection Advice for Pneumatic Air Cylinders

Before you place an order, ask yourself these key questions:

1. Load and Output Force

The cylinder’s thrust must meet your load requirements. The force calculation formula is:

F orce=E f f ectivearea×W or kingpressure

It’s wise to select a cylinder with some force margin to avoid insufficient power due to load changes.

2. Stroke Length

The stroke determines the movement distance of the piston. Too short a stroke limits motion range; too long wastes space and increases cost. Measure your required stroke accurately and choose the most suitable length.

3. Working Pressure and Air Supply

Different cylinders operate at different pressure ranges. Ensure your air supply is stable and meets the cylinder’s requirements to avoid performance issues.

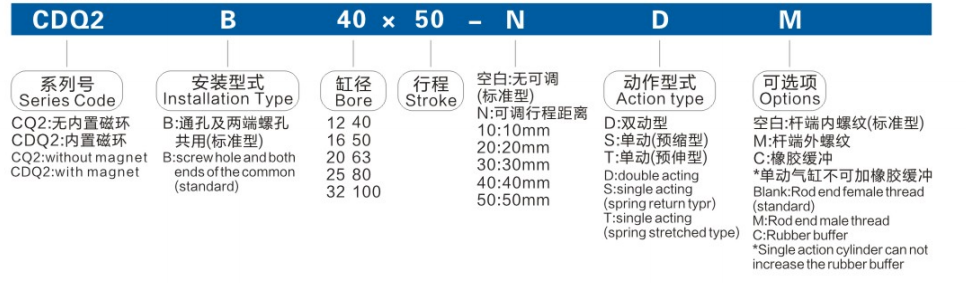

4. Mounting Method and Space Limitations

There are various mounting options—flange, foot, clevis, etc. If space is tight, compact cylinders are a smart choice. The mounting method affects stability and ease of maintenance.

5. Speed and Response Time

Cylinder speed depends on air pressure and flow. Fast response is needed for high-speed automation; slower speeds suit precise positioning. Adjust the cylinder and matching valves as needed.

6. Environmental Adaptability

Cylinder materials and seals must suit the working environment. High temperature, humidity, or corrosive conditions require special materials and seals to ensure cylinder life.

7. Sensing and Control Needs

Modern automation often requires cylinders with magnetic sensors for position feedback and precise control. Consider whether you need this feature.

Common Selection Mistakes

- Oversized Selection: Wastes money and is harder to install.

- Undersized Selection: Insufficient force, lowering productivity.

- Ignoring Environmental Factors: Shortens cylinder lifespan.

- Neglecting Maintenance Convenience: Increases future maintenance costs.

Daily Maintenance Tips

- Regularly check the cylinder surface and seals.

- Keep the air supply clean and prevent debris from entering.

- Replace vulnerable parts as recommended by the manufacturer.

- Listen for unusual noises and check for smooth operation.

Choosing the right pneumatic cylinder will keep your equipment running smoothly and boost production efficiency. Don’t let selection mistakes or neglected maintenance become obstacles in your production. If you’re still unsure about selection or facing usage problems, feel free to contact us. With extensive experience in pneumatic air cylinder supply and technical support, we’re dedicated to providing tailored solutions for every customer.

FAQ about Pneumatic Air Cylinder

What should I do if there is a leak in the pneumatic air cylinder?

Leaks usually result from worn seals or loose fittings. Regularly check seals and tighten fittings. Replace aging seals promptly.

What causes insufficient thrust or weak motion?

Possible causes include low air pressure, damaged seals, or clogged air lines. Check your air supply and clean the air lines. Replace seals if needed.

Why is the stroke incomplete or movement slow?

Unstable air supply, piston sticking, or poor lubrication can cause this. Keep the air supply stable, lubricate the piston rod regularly, and clean out internal debris.

Why is the piston rod damaged?

Excessive side load or improper installation are common causes. Ensure the cylinder is installed vertically and avoid side loads.

What causes overheating or seal failure?

Poor lubrication and high ambient temperature lead to seal aging. Use seals suitable for high temperatures and maintain proper lubrication.

Visit our website at https://hosepneumatic.com/ for more product information and expert advice. Let’s work together to take your industrial automation to the next level! Send us an inquiry now and start your journey to efficient pneumatics!