In the world of pneumatic systems, Stainless Steel Mini Cylinder are the unsung heroes, providing precise motion control and durability in demanding environments. These cylinders are particularly valued in industries like food processing, pharmaceuticals, and medical devices, where cleanliness and reliability are non-negotiable. Selecting the right Stainless Steel Mini Cylinder is crucial, as it directly impacts system performance and longevity. This guide will walk you through the key considerations for choosing these critical components.

Understanding the Working Environment

Temperature Range

Stainless Steel Mini Cylinders are designed to operate within specific temperature ranges. Ensuring that the chosen cylinder can withstand the temperature fluctuations in your application environment is vital. For instance, some cylinders are suitable for extreme temperatures, making them ideal for applications with significant thermal variations.

Corrosive Environments

In environments where exposure to corrosive substances is a concern, stainless steel’s excellent resistance to corrosion makes it an ideal choice. The specific grade of stainless steel (e.g., 304 or 316) can further enhance resistance to different types of corrosives. For example, in marine environments, 316 stainless steel is often preferred due to its superior resistance to saltwater corrosion.

Humidity and Dust Protection

For applications in humid or dusty environments, ensuring that the cylinder has adequate sealing and protection is crucial. Features like dust caps or additional sealing elements prevent moisture and debris from entering the cylinder.

Determining Work Requirements

Load and Force Requirements

The load and force requirements of your application dictate the size and type of Stainless Steel Mini Cylinder needed. Calculating the maximum force required to move the load efficiently is essential. Oversizing can lead to wasted energy, while undersizing may result in inadequate performance. For instance, in a manufacturing line, accurately sizing the cylinder ensures that it can handle the weight of moving parts without straining the system.

Speed and Stroke

The speed at which the cylinder operates and the stroke length required are also critical factors. Some applications demand high-speed operation, while others require longer strokes. Ensuring that the chosen cylinder can meet these demands without compromising reliability is essential. For example, in high-speed assembly lines, cylinders with adjustable air cushioning can help control the piston’s speed at the end of its stroke, reducing noise and vibration.

Product Features and Parameters

Reliability and Lifespan

Reliability is paramount in pneumatic systems. Look for cylinders that have undergone rigorous testing to ensure they can withstand repeated cycles without significant wear. The lifespan of the cylinder directly impacts maintenance costs and system downtime. A longer lifespan means fewer replacements and less downtime, which can significantly reduce operational costs over time.

Sealing Performance

Good sealing performance is essential to prevent air leaks, which can lead to inefficiency and increased energy costs. Ensure that the cylinder’s seals are designed to maintain integrity over time and under various operating conditions. High-quality seals can also reduce the need for frequent maintenance.

Material and Structure

Stainless steel offers several advantages, including resistance to corrosion, ease of cleaning, and aesthetic appeal. The structure of the cylinder should also be considered, with options like compact designs or specialized mounting configurations available to suit different applications. For example, compact cylinders are ideal for applications where space is limited, such as in robotic arms or precision machinery.

Stainless Steel Mini Cylinder Series Introduction

Series Overview

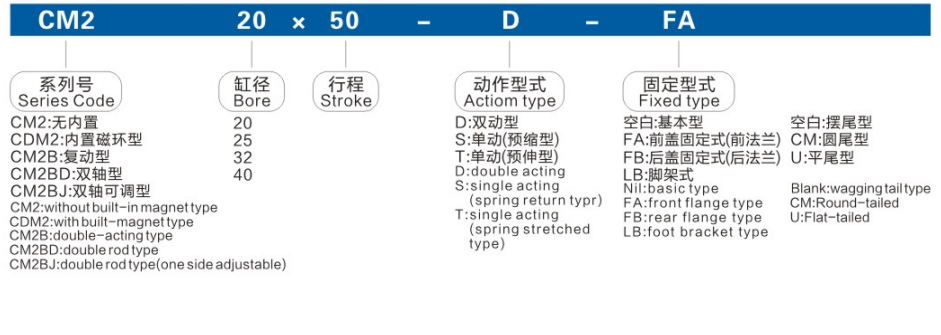

Different series of Stainless Steel Mini Cylinders offer unique features tailored to specific applications:

- Cylinder Diameter: Available in various diameters to suit different force requirements.

- Operation Type: Both single-acting and double-acting options are available, depending on whether the cylinder needs to be returned to its original position by an external force or by the air supply itself.

- Adjustable Air Cushioning: This feature helps control the speed of the piston at the end of its stroke, reducing noise and vibration.

Specialized Features

Some cylinders may offer specialized features such as enhanced corrosion resistance or specific mounting options. Understanding the specific advantages of each series can help in selecting the most appropriate cylinder for your application.

Installation and Maintenance

Installation Methods

Stainless Steel Mini Cylinders can be installed using various methods, including:

- Nut Mounting: Simple and effective for most applications.

- Flange Mounting: Provides a secure and stable connection.

- Foot Mounting: Useful for applications where the cylinder needs to be securely fastened to a surface.

Maintenance and Durability

While stainless steel cylinders are durable, regular maintenance is still necessary to ensure optimal performance. This includes checking for signs of wear, cleaning the cylinder, and replacing seals as needed. The cost-effectiveness of these cylinders lies in their long lifespan and low maintenance requirements.

In conclusion, selecting the right Stainless Steel Mini Cylinder involves careful consideration of several factors, including the working environment, load requirements, product features, and installation needs. By understanding these elements and choosing a cylinder that aligns with your application’s demands, you can ensure reliable operation, reduce maintenance costs, and enhance overall system efficiency. Whether you are working in a cleanroom environment or a harsh industrial setting, the right Stainless Steel Mini Cylinder can make all the difference in achieving your goals. For further guidance or to explore specific product options, consulting with a knowledgeable supplier or engineer can provide valuable insights tailored to your unique needs.